Multi-functional Pharmaceutical Experiment System

Introduction:

SD-II Multi-functional Pharmaceutical Experiment System is a small size equipment for advanced development of pharmaceuticals used in the laboratory. It can be widely used in the research, experiment and production in the pharmaceutical, chemical, food stuff and cosmetic industries. This system features the all purpose driving unit that can be attach with various kinds of accessory equipment of different functions, to realize the purpose of stirring, mixing, vibrating granulation, homogenzing, palleting, pressing, sugar coating etc.

Feature:

1.Full-featured, compact appearance, covering small.

2.Adopts PLC control system & touch Screen, simple operation and convenient.

3.Accessories diversification, on-demand feature, easy removal.

4.Stainless steelSS316L, no dead ends, easy cleaning and maintenance, compliance with GMP requirements.

Supplementary Machines:

- Oscillating Granulator

Oscillating Granulator adopts rocking and rotating granular solids to make granular solids pass the desired mesh belt, with its max productivity of 30 kg/h, which depends on the materials and the meshes of two different sizes.

- Vibrating Screens

When rocking, it forces the granular solids to be screened by mesh, so you can choose the desired materials of mesh standard. There are screens of two sizes.

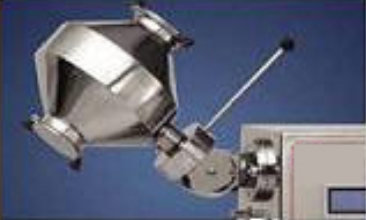

- Sugar Coating Pan

It adopts a universal gear to connect all kinds of sugar coating balls and the driving main engine, facilitating operators to produce sugar coating materials uniformly in a correct angle. It is possible to equip with a electric air heater with a fixed pole above the ball, to bake promptly

- Double Cone Mixer

It is available for all powder and granular materials that can flow freely. All these materials can make multi-dimensional motion during the operation in it, so as to be mixed well. This machine is made of stainless steel, connected to the driving main engine simply.

- Cube Mixer

The cube mixer adopts turn-over motion to mix the materials well and moderately, so this machine is extremely suitable for materials of high sensibility. It is equipped on a universal gear , able to rotate at any a degree between 0—75, facilitating operators to increase or reduce the mixing intensity. It is good for uniform mixing by taking advantage of three strategic stainless steel.

- Stirrer Mixer

The machine can mix all kinds of liquid with high and low viscosity. The stirring is finished by artificiality The container and stirrer mixer are both made of stainless steel. You can choose invariable temperature heating chuck containers or containers for both cooling and heating

- Trough Type Mixer

It adopts a Z-chip to rotate in the groove container in different angles. It is made of stainless steel, with the different speed and the outline of stainless chip, it mixes materials very well. The whole container can rotate at a 180 degree after cutting off the power, so it is easy to discharge and to be cleaned. You can change invariable temperature cooling and heating jigs.

- V Type Mixer

V Type mixer is made of stainless steel, composed of two Unsymmetrical cylinders. It can makes the materials pump heavily or slightly, bounce and lead to uniform mixing by alternate motion, with no dead angle and no accumulating materials. It is speedy , clean and convenient

- Super Agitating Mixer

All types of high viscosity or low viscosity liquid can be mixed in this equipment. Mixing status adopts artificial movement. The container and mixer are made of stainless steel. Constant temperature controlling heating layer container and cold or hot container are optional.

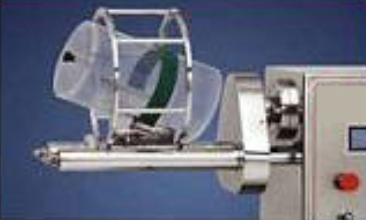

- Pelletiser GTE (300MM o.d.)

The pelletiser GTE (300 mm o.d.) is attached to the U&M-II via the universal gear UG which enables the operator to adjust the operating angle to the optimum position during operation. The material can be fed in manually or continuously. The rotary movement of the pan carries the product to the top of the pan and then flows down the pan in an even stream to the base. By addition of the requisite amount of liquid, this process can be converted into the formation of pellerts. The angle of the pan and the amount of liquid added determines the pellet size. When the pan is full, the pallets will continuously roll over the edge of the pan into a waiting container. All parts coming into contact with the product are made of stainless steel.

- Cubic Mixer

Mixer using three-dimensional rolling action to produce uniform blending, mixing action extreme moderate, the device particularly suitable for sensitive and strong materials. Gear in general, can be 0 ~ 75 ° angle for any arbitrary adjustment to increase or decrease the intensity of mixing action. With the strategic side cloth body was three rows of stainless steel rods to supplement the mixing of materials.

|

Model |

SD-II |

|

Power |

220V/0.55KW |

|

Rotating Speed |

0-120r/min |

|

Dimension |

580×500×600 mm |

|

Weight |

50Kg |

.png?x-oss-process=image/resize,w_100/quality,q_100)