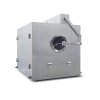

High Efficiency Intelligent Poreless Film Coating Machine

Basic Working Principle:

The tablets make complicated and constant track movement with easy and smoothturning and frequent exchanging in a clean and closed drum of the film coating machineThe coating mediums stirred in the constant temperature controlled stirring drum aresprayed on tablets through the spray gun at the inlet under the action of crawler pump.Meanwhile hot air up to 100,000 level filtration are inhaled through the air distributingpipe at the centerof the drum and flowed through tablets around the fan blade. Underthe action of air exhaustand negative pressure, hot air are exhausted from the anotherside of the air distributing pipe and discharged after dust abatement. So these coatingmediums on the surface of tablets get dry quickly, forming a coat of firm, fine andsmooth film. Automatically controlled by PLC, it is in normal operation.

USE:

It's a kind of equipment integrating elegance, high efficiency ,safety, easy toclean, which is applied for coating traditional Chinese and Western tabletsand pills, including the micro pills and granulated pills, small pills, water pills,drip and granulated pills, with sugar, organic film, water soluble, film andprogrammable PLC ( machine and person interface),with which itsoperation process and process parameters such as negative pressure andtemperature can be automatically controlled lt's easy to operate, with reasonableand advanced process during run of the machine. Main machine, cleaningsystem, hot air cabinet, exhaust cabinet and the thermostatic mixing drumare all made of imported high quality, stainless Steel, which conforms to GMPrequirements. This product hs passed the certification of EU .

-

Air Distributing Pipe

Performance and Characteristics:

The drum of the main machine has a closed poreless structure and is equipped with a flow-guiding sheet. Tablets can make easy and smooth rotationwithout fragment and chipped edge in the drum due to mirror polshing of its wall and fow-guiding sheet which greatly improves the yeld. The peroratemachine has a wide application, energy and auxiliary saving and easier to clean.

During air intake, three times fltration involving primary fltration, medium fltration and high fltration, can reach 100,000 level purification. During aiexhaust, dust abatement can reach 99% by adopting a bag-type dust extractor.

A specially designed air source exchange system features exchange of hot air an cold air depending on the technological requirements, so to say, thefan propeler can be regarded as air nlet or air outlet. The propeller hole bore can meet the user's requirement from 0.6 to 3.00 mm, which can besuitable for all type of tablet coating.

An eye detecting explosion-proof lamp is equipped in the drum so as to clearly view all material in run for the convenience of accurately control of coating technological in range.

-

Japaness Spray Gun

-

Fan Propeller

-

Wriggle pump

| Model Items |

BGW300 | BGW150 | BGW80 | BGW40 | |

| Load capacity | 300kg/time | 150kg/time | 80kg/time | 40kg/time | |

| Revolutions(R/Min) | 1-13RPM | 1-16RPM | 1-19RPM | 1-21RPM | |

| Machine power | 3kw | 2.2kw | 1.5kw | 0.75kw | |

| Diameter of coating drum | 1500mm | 1280mm | 1006mm | 825mm | |

| Power of air exhaust cabinetmotor | 7.5kw | 5.5kw | 3kw | 2.2kw | |

| Air exhaust flow | 10000m^3/h | 7419m^3/h | 5266m^3/h | 3517m^3/h | |

| Power of hot air cabinet motor | 2.2kw | 1.5kw | 1.1kw | 0.75kw | |

| Hot air flow | 3517m^3/h | 2356m^3/h | 1685m^3/h | 1285m^3/h | |

| Weight of main machine | 1200kg | 1000kg | 800kg | 550kg | |

| Air conusumption | Pressure | >0.4Mpa | >0.4Mpa | >0.4Mpa | >=0.4Mpa |

| Air comsumption | 1.1m^3/min | 0.7m^3/min | 0.35m^3/min | 0.15m^3/min | |