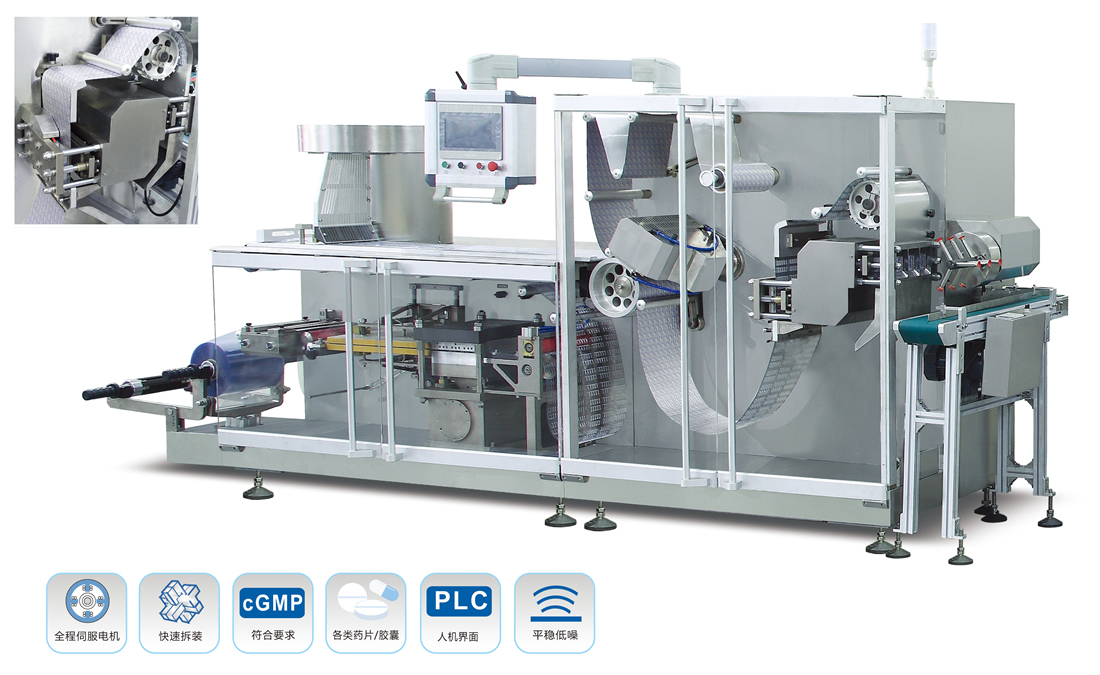

DPH-260/350

High speed roller plate aluminum-plastic blister packaging machine

This machine is suitable for capsules, tablets and other conventional drugs, but also can be used in milk tablets, lozenges, chewing gum, chocolate beans and other products automatic high-speed blister packaging. Adopts flat plate positive pressing forming, PVC blister shape is expanded evenly; Roller mesh line seal, beautiful appearance and reliable sealing effect; Batch number adopts easy to change design, which is convenient to change daily under the premise of ensuring the effect; Blanking station can be designed for ordinary blanking or micro-edge blanking and boundless blanking mode, which can greatly save material cost, reduce labor cost and material cost to a minimum, and greatly improve the production efficiency of enterprises.

High-speed aluminum-plastic blister packing machine adopts servo bow | mechanical transmission design, with high degree of automation, fast replacement parts and working mode, low failure rate. It can realize the perfect match and docking with the machine such as the box filling machine, and meet the packaging requirements of various versions and various lines.

| Machine type | DPH260 | DPH350 |

| Productive capacity | Aluminum /plastic : 60-150/min | Aluminum (AL/AL): 40-80/min |

| Maximum wire speed of packaging material | 20m/min | 22m/min |

| Maximum forming depth | 12mm | 12mm |

| Maximum molding area | 260X250mm | 350X230mm |

| Maximum width of packing material | 260mm | 350mm |

| Maximum feed length | 250mm | 230mm |

| Maximum punching length | 120mm | 120mm |

| Power source | AC380V/ Three-phase /50Hz 1 8kw/h | AC380V/ Three-phase /50Hz 20kw/h |

| stress | 0.6MPa | 0.6MPa |

| Air consumption | < 12 m3/h | < 16 m3h |

| temperature | 15-18°C | 15-18°C |

| Water consumption | 0.08 m3/h | < 0.1 m3h |

| Overall dimension | 3860X1135X1725mm | 4600X1380X1930mm |

| weight | It is About 3000kg | It's About 3500kg |