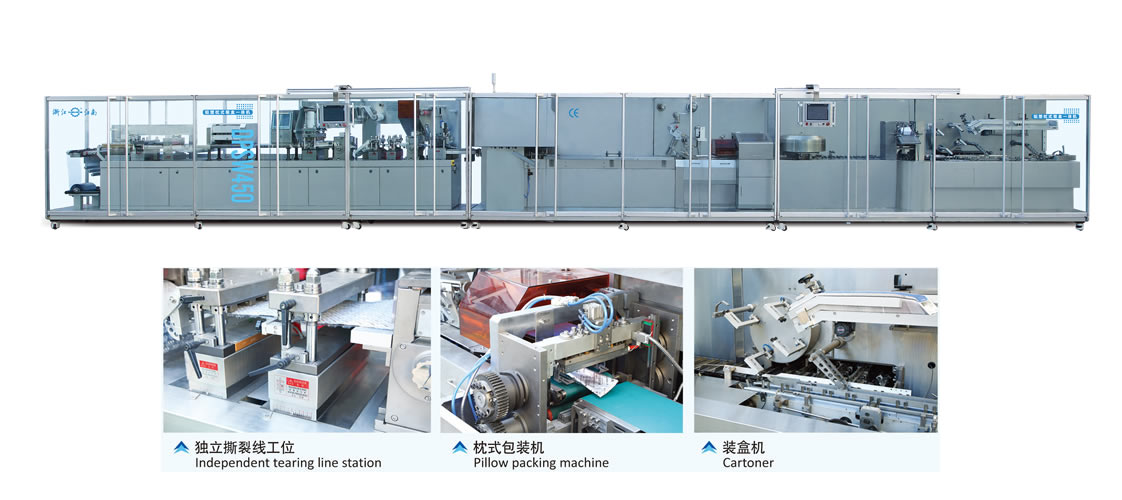

DPSW-450

Bubble cover/pillow type/boxing/boxing integrated machine

Performance Characteristics:

■ Visual design of tempered glass, easy to observe the working state and maintenance of the machine; The machine enters the stop state when the shield is opened.

■ Movable man-machine interface, easy to debug; And there are multiple emergency stop buttons on the whole line.

■ The servo motion control system runs the whole line, and has a memory function, that is, stop, power off, without resetting equipment parameters, automatically record the last stop point position to continue running.

■ Mold positioning design, easy to replace fast.

■ Blister section buffer design to reduce blister shrinkage.

■ Air and water integrated cooling station.

■ Scrap is chopped and discharged without stopping for collection.

■ Hard connection of upstream and downstream equipment, continuous feeding, the number of various plate pillow bags can be set on the touch screen.

Main technical parameters:

| Total power of supply | 380V 50Hz 25Kw |

| Air pump capacity | 20.25m3/min (Self Prepared) Pressure: 0.6-0.8Mpa |

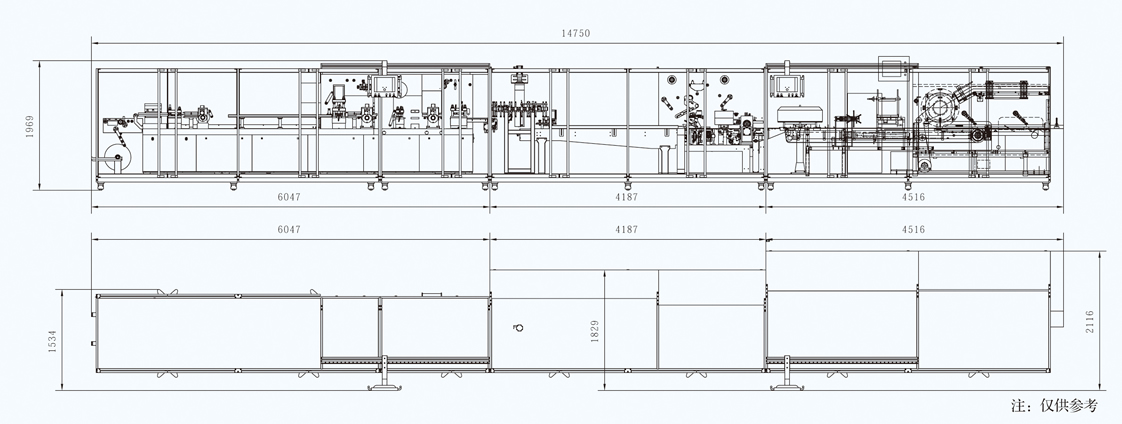

| Overall dimension | 14800x1200x1740mm can be split, including the height of the foot |

|

Net weight |

7000KG |

DPP-300K Blister machine

| Blanking frequency (standard) | Aluminum plastic AL/PVC: 150 cuts/min Max | Aluminum Aluminum AL/AL: 90 ce/min Max |

| Maximum molding area and depth | Aluminum /PVC: 200x300x15mm | ALAL: 200x300x12mm |

| Packaging material |

Non-toxic PVC hard sheet (0.15-0.4)x310x(medium 600)mm |

|

|

Heat seal aluminum foil (0.02-0.15)x310x(medium 300)mm |

||

|

Aluminum foil (0.16-0.2)x310x(medium 600)mm |

||

| Heat seal dialysis paper (50-100)g/max310x(30)mm |

ZH-450 Packing machine

| Packing speed | ≤450 boxes /min Box/min |

| Quality requirements (Cartons) | 250-350g/m2(subject to availability) |

| Size range (carton) | (90-160)x (35-90)x(15-50)mm |

| Quality requirements (Instructions) | 70-80g/m2(subject to availability) |

| Open size range (manual) | (90-250)x(90-180)mm(L x W) |